MIK-TDS210-B Conductivity Controller for Conductivity Measuring in Industrial/Lab Process

Introduction

The MIK-TDS210-B Conductivity/Hardness/Resistivity Online Analyzer is an intelligent industrial analyzer designed for continuous online monitoring of liquid quality parameters, including electrical conductivity (EC), total dissolved solids (TDS), resistivity (ER), and temperature.

It integrates advanced signal processing and multiple communication interfaces, enabling reliable measurement and seamless integration with automated control systems.

This instrument is widely adopted across diverse industrial sectors, including thermal power, chemical fertilizer production, environmental protection, metallurgy, pharmaceuticals, biochemistry, food processing, and water treatment, where real-time liquid quality data supports process optimization and compliance.

Working routine

The operational routine of the MIK-TDS210-B analyzer consists of three fundamental stages:

1. Sensor Signal Acquisition

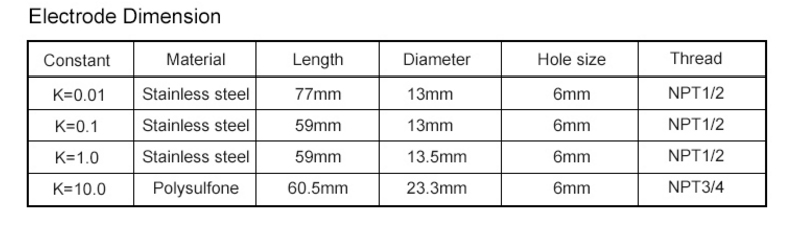

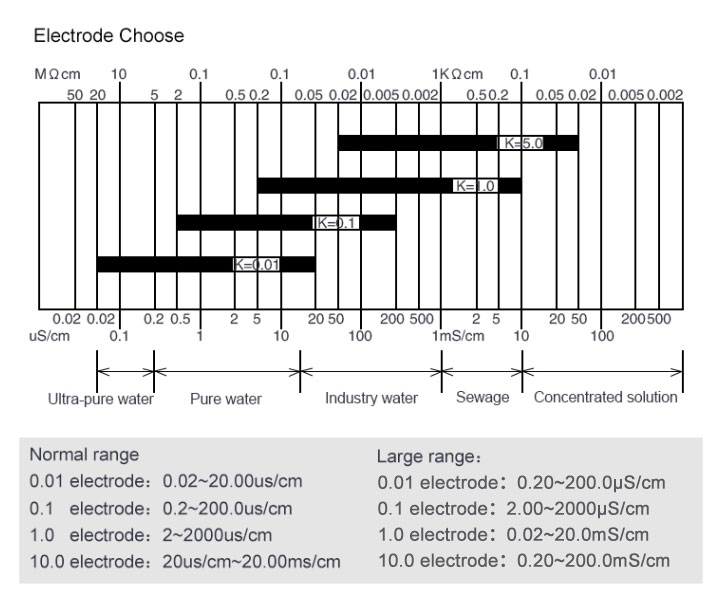

The analyzer continuously receives signals from a conductivity sensor (electrode) installed in the liquid stream. The sensor detects ionic content in the solution, providing raw conductance data that reflects EC/TDS/ER levels. Multiple electrode constants are supported, enabling measurement across a broad range of conductivity values from low-ionic solutions to higher conductivity industrial streams.

2. Data Processing and Compensation

Once sensor signals are captured, the built-in electronics apply temperature compensation using either manual or automatic adjustment to correct for temperature-dependent changes in conductivity.

The instrument calculates accurate conductivity, TDS, and resistivity values by converting measured conductance into standardized units. Configurable system parameters such as upper/lower limit warnings, temperature offset, and delay settings help tailor the response to specific process requirements.

3. Output and Integration

Processed measurement results are output through multiple interfaces. The standard 4–20 mA analog signal, relay outputs, and RS485 digital communication (Modbus-RTU) provide compatibility with distributed control systems (DCS), programmable logic controllers (PLC), and remote monitoring solutions. Isolated transmitting outputs and RS485 communication help reduce interference and maintain signal integrity in industrial environments.

Specification

| Product | TDS meter, EC controller |

| Model | TDS210-B |

| Measure range | 0.01 electrode: 0.02~20.00us/cm |

| 0.1 electrode: 0.2~200.0us/cm | |

| 1.0 electrode: 2~2000us/cm | |

| 10.0 electrode: 0.02~20ms/cm | |

| Accuracy | EC/TES/ER: ±0.1%FS

NTC10K: ±0.3℃ PT1000: ±0.3℃ |

| Measuring medium | Liquid |

| Temp compensation | Manual/ Auto temperature compensation |

| Temperature Range | -10-130℃, NTC10K or PT1000 |

| Communication | RS485, Modbus-RTU |

| Signal output | 4-20mA, maximum loop 750Ω, 0.2%FS |

| Power supply | AC: 220V±10%, 50Hz/60Hz

DC: 24V±20% |

| Relay output | 250V, 3A |

Applications

The MIK-TDS210-B online analyzer is suitable for a wide range of fluid quality monitoring and process control applications:

Water Treatment and Supply Systems

In municipal and industrial water systems, real-time measurement of conductivity, TDS, and resistivity supports assessment of water purity, scaling potential, and the effectiveness of treatment stages.

Thermal Power and Energy Generation

Conductivity and resistivity measurements are critical in boiler feedwater and condensate systems, where ion concentrations must be controlled to prevent corrosion and maintain thermal efficiency.

Chemical Fertilizer and Process Industries

In chemical manufacturing environments, continuous monitoring of conductivity and TDS ensures that solution compositions remain within specified parameters, supporting process stability and product quality.

Environmental Protection and Regulatory Compliance

Environmental monitoring programs use conductivity and TDS data to detect changes in discharge streams or surface waters, helping industries comply with effluent standards and protect ecosystems.

Metallurgy and Surface Treatment

Process streams in metal finishing, plating, and electrochemical operations require tight control of ionic content, which can be achieved through online conductivity monitoring.

Pharmaceutical, Biochemistry, and Food Production

These sectors rely on accurate liquid quality analysis to maintain hygienic conditions, control process chemistry, and ensure product integrity through all stages of production.